OptoSort® series APOLLO

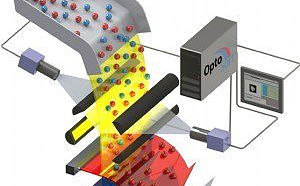

Freefall sorter with sensor-based detectors for optical & spectral sorting.

With the APOLLO series from OptoSort, high quality materials can be pre concentrated in order to save energy, water and chemicals in the production of a saleable final product. This not only leads to a cost reduction in the extraction of natural resources, but also makes the manufacturing process much more efficient. Depending on the particle size and material density, throughput rates of up to 200 tonnes per hour are possible.

Revolutionary sorting system - The combination of advanced sensor technologies, fast and intelligent detection systems and proven separation technology enables separation of interference and foreign substances efficiently in order to ensure the highest product purities throughout the material extraction process.

Detectors for reliable sorting - A number of different detectors are used for seperation of the particles. The type of equipment that best meet your purpose, depends on the respective material sample.

-

RGB – colour sorter

-

HSI – hyperspectral imaging sorter

-

RGB & HSI - combination sorter

-

Sorting with a selective metal sensor

Sorting, an indispensable instrument for the economy - Conventional tailings still contain large amounts of valuable raw materials that can be efficiently recovered by using OptoSort sorting systems. If the majority of waste rock is sorted after primary crushing, or even underground, the cost of transport and beneficiation can be reduced. Sorting pays off at any rate!